Top 10 Food Machinery Innovations You Must Know About in 2023

In the rapidly evolving world of food production, the significance of food machinery cannot be overstated. As we delve into 2023, numerous innovations have emerged, transforming the way we process, package, and distribute food products. These advancements not only enhance efficiency but also improve food safety and sustainability, addressing the modern consumer's demand for higher quality and better practices in food handling. The current landscape showcases a variety of cutting-edge technologies designed to streamline operations, reduce waste, and promote healthier food options.

This article highlights the top 10 food machinery innovations of 2023 that are reshaping the industry. From automation in food processing to sophisticated packaging solutions, each innovation exemplifies the drive towards smarter and more sustainable food production methods. As we explore these breakthroughs, it becomes evident that the integration of technology within food machinery is not merely a trend, but a vital component in catering to the increasing global food demand while maintaining environmental responsibility. Join us on this journey to discover how these groundbreaking advancements are setting the stage for the future of the food industry.

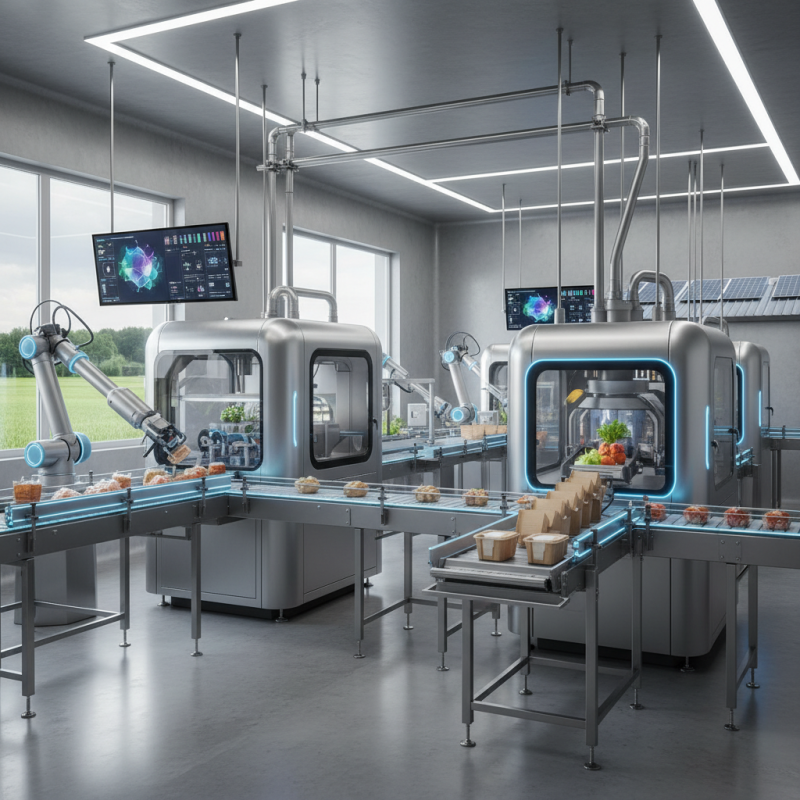

Emerging Trends in Food Machinery for 2023

In 2023, the food machinery sector is experiencing transformative innovations driven by the increasing demand for efficiency and sustainability. One of the most significant trends is the integration of artificial intelligence and machine learning into food processing technologies. According to a recent report by Mordor Intelligence, the global market for AI in food and beverage is projected to reach over $5 billion by 2025, growing at a compound annual growth rate (CAGR) of 46%. These technologies enhance operational efficiency, reduce waste, and improve product quality through predictive maintenance and process optimization.

Another noteworthy trend is the shift towards automation and smart manufacturing within the food industry. The International Federation of Robotics projects a 20% increase in the adoption of food robots between 2023 and 2025. This surge is fueled by labor shortages and the need for increased productivity. Automated systems not only streamline operations but also minimize human error and ensure consistent product quality. Enhanced robotics and automation capabilities allow manufacturers to respond quickly to consumer demands while adhering to strict safety regulations. As these technologies evolve, they will play a crucial role in shaping the future of food machinery and its contribution to sustainable food production.

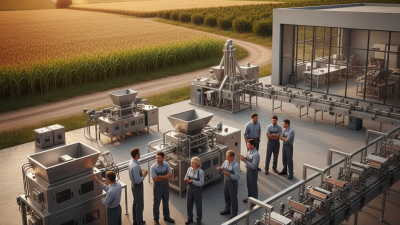

Key Innovations in Automation Technologies for Food Production

In 2023, the food production industry has seen significant advancements in automation technologies that are reshaping the way food is processed and packaged. One of the key innovations is the integration of artificial intelligence (AI) and machine learning into production lines. These technologies enable machines to analyze data in real-time, allowing for predictive maintenance that reduces downtime and enhances efficiency. By optimizing operational processes, manufacturers can ensure higher productivity while maintaining consistent product quality.

Another noteworthy development is the use of robotics in food handling and packaging. Automated robotic systems are increasingly capable of performing complex tasks, such as sorting, packing, and even delicate operations like slicing and dicing. With enhanced precision and speed, these robots not only streamline workflows but also mitigate the risks associated with manual labor, such as injuries and contamination. Additionally, the implementation of collaborative robots, or cobots, allows for safer human-robot interaction, further improving the dynamics of production environments. These advancements signal a transformative era in food automation, promising both efficiency and safety throughout the supply chain.

Sustainable Practices in Food Machinery Design and Usage

As the food industry continues to evolve, sustainable practices in food machinery design and usage have become paramount. Innovations in this field are not only focusing on efficiency but also on reducing environmental impact. By incorporating energy-efficient components, manufacturers are making strides to minimize power consumption during production. For instance, machinery that utilizes solar energy or recycles heat can significantly lower operational costs while contributing to a more sustainable future.

Tips for implementing sustainable practices include regularly maintaining equipment to ensure optimal performance and longevity, which in turn reduces waste. Additionally, investing in machinery that is designed with eco-friendly materials can enhance sustainability efforts. Businesses should also consider partnerships with technology providers that prioritize environmental responsibility, as collaboration can lead to shared innovations and greater environmental benefits.

Furthermore, the adoption of smart technology in food machinery helps monitor energy use and resource consumption, allowing businesses to make data-driven decisions towards sustainability. Implementing IoT solutions can provide insights into production efficiencies and areas where waste can be reduced. This approach not only helps in abiding by environmental standards but also fosters a culture of sustainability within organizations, ultimately leading to long-term benefits for both the industry and the planet.

Impact of AI and Machine Learning on Food Processing Equipment

In 2023, the integration of AI and machine learning in food processing equipment is revolutionizing the industry. These technologies enhance the precision and efficiency of food manufacturing, enabling companies to optimize production processes and reduce waste. For instance, AI-driven systems can analyze vast amounts of data to predict equipment failures before they occur, thus minimizing downtime and ensuring a smoother operation. Moreover, machine learning algorithms can adjust processing parameters in real-time, improving product quality and consistency while lowering energy consumption.

Tips for implementing AI in your food processing facility include starting with small pilot projects to identify areas of effectiveness before scaling up. Investing in training for your staff to understand the technology is crucial, as human oversight remains essential in a tech-driven environment. Additionally, focusing on data collection and management can pave the way for more informed decision-making, allowing you to leverage AI tools to their fullest potential.

Another important aspect is the consideration of food safety regulations and standards when integrating AI and machine learning. It’s essential to ensure that automated processes meet compliance requirements to avoid any operational setbacks. By striking a balance between innovation and regulatory considerations, food manufacturers can maximize their competitive edge while maintaining public trust in their products.

Top 10 Food Machinery Innovations in 2023

This chart illustrates the impact of AI and Machine Learning on various food processing equipment innovations in 2023.

Revolutionary Advances in Food Safety and Quality Control Technologies

In 2023, innovation in food safety and quality control technologies has reached unprecedented levels, significantly enhancing how the food industry ensures product integrity. According to a report by the Food Safety and Inspection Service, the integration of artificial intelligence (AI) in food processing has reduced contamination rates by over 30% in various sectors. This advancement allows manufacturers to predict potential hazards through real-time monitoring, enabling preemptive actions that optimize food safety protocols.

Moreover, the rise of blockchain technology in supply chain management has provided unprecedented transparency and traceability. A study conducted by the Institute of Food Technologists indicated that systems utilizing blockchain can trace food products from farm to table in under two minutes, enhancing consumer confidence and reducing the likelihood of foodborne illnesses. These revolutionary technologies not only streamline compliance with stringent food safety regulations but also address growing consumer demands for transparency, ensuring that quality control is at the forefront of the food industry’s evolution in the coming year.