Top Food Making Machinery Trends to Watch in 2025

The food making machinery industry is poised for significant transformation by 2025, driven by advancements in technology and changing consumer preferences. According to a recent report by Mordor Intelligence, the global food processing machinery market is expected to grow at a CAGR of over 6% from 2022 to 2027, indicating a robust demand for innovative solutions that enhance efficiency and sustainability. As manufacturers adopt smart technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), they are able to optimize production processes and reduce waste, aligning with the increasing emphasis on eco-friendly practices.

Industry expert Dr. Timothy Green, a noted authority on food manufacturing technology, emphasizes the importance of these trends, stating, “The future of food making machinery lies in automation and data-driven solutions that not only improve operational efficiency but also cater to consumer demands for transparency and quality.” As we look ahead to 2025, it is clear that the landscape of food making machinery will increasingly reflect these technological innovations, ultimately transforming how food products are processed, packaged, and delivered to consumers worldwide.

With an eye toward sustainability and efficiency, the exploration of these trends will provide valuable insights into the future of the food making machinery industry. By embracing these changes, companies can position themselves strategically within an evolving market, ensuring their resilience and competitiveness in the years to come.

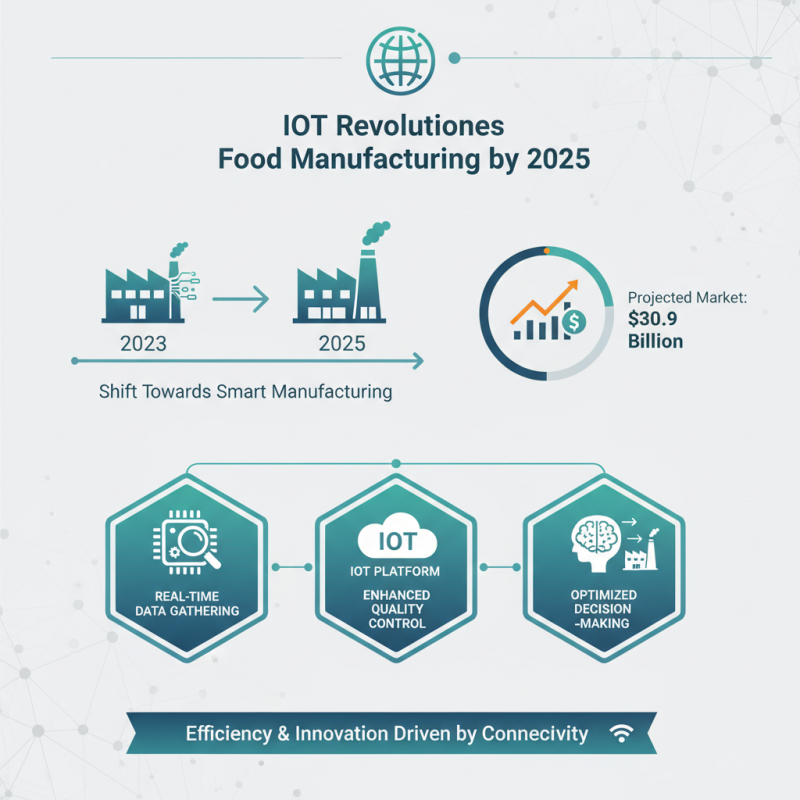

Emerging Automation Technologies in Food Making Machinery by 2025

The food manufacturing industry is on the brink of a technological revolution as automation technologies continue to evolve rapidly. According to a report by MarketsandMarkets, the food robotics market is anticipated to reach $3.3 billion by 2025, driven by the need for efficient production processes and labor cost reduction. Robotics, particularly in packaging and palletizing, are key trends that will reshape operations, allowing for increased speed and accuracy while minimizing human intervention.

Moreover, the integration of artificial intelligence (AI) and the Internet of Things (IoT) into food manufacturing machinery is set to enhance productivity and quality control. A study by Fortune Business Insights forecasts the IoT in the food and beverage market will grow from $8.6 billion in 2021 to $31.8 billion by 2028, highlighting the growing significance of smart equipment that can monitor processes in real-time. This interconnected machinery provides data analytics, enabling manufacturers to predict maintenance needs, optimize production schedules, and improve overall efficiency.

By 2025, these emerging automation technologies are not only expected to streamline operations but also to contribute significantly to sustainability goals within the food industry. Embracing environmentally friendly practices through automation can lead to reduced waste and energy consumption, aligning with the growing consumer demand for eco-conscious products. With such advancements on the horizon, the food making machinery sector is poised for transformative growth, underpinned by innovation and automation.

Sustainability Trends Driving Innovations in Food Production Equipment

As sustainability becomes a pivotal concern in food production, machinery innovations are evolving to meet these demands. In 2025, we can expect to see a surge in equipment that minimizes waste and enhances energy efficiency. Technologies like water-saving systems and energy-efficient motors are being integrated into food-making machinery, thereby reducing the environmental footprint of food production processes. These advancements not only help in conserving natural resources but also enable manufacturers to meet increasingly stringent regulations regarding environmental sustainability.

**Tips for Implementing Sustainable Machinery:**

1. Evaluate your current machinery for energy efficiency and identify potential upgrades.

2. Invest in technologies that recycle water and materials, which can significantly reduce waste.

3. Consider sourcing local materials for your equipment to lower transportation emissions and support the circular economy.

Furthermore, automation and smart technologies play a crucial role in sustainability trends. By incorporating IoT (Internet of Things) into food production lines, manufacturers can monitor energy and resource usage in real-time. This not only leads to optimized operations but also facilitates proactive adjustments that reduce waste and maximize efficiency. The fusion of technology with sustainable practices will shape the future landscape of food-making machinery in profound ways.

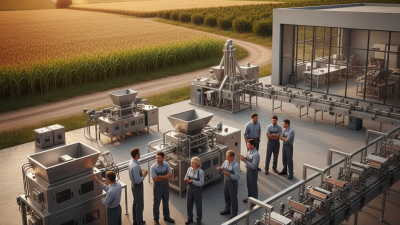

Impact of IoT on Food Manufacturing Efficiency and Quality Control

The integration of the Internet of Things (IoT) in food manufacturing is set to revolutionize efficiency and quality control in the industry by 2025. IoT technologies enable manufacturers to gather real-time data from connected devices throughout the production process, leading to enhanced decision-making and operational performance. According to a 2023 report by MarketsandMarkets, the IoT in the food and beverage market is projected to reach $30.9 billion by 2025, demonstrating a significant shift towards smart manufacturing practices.

One primary benefit of IoT implementation is the ability to monitor equipment and environmental conditions continuously. For instance, temperature and humidity sensors can ensure that food products are stored and processed under optimal conditions, minimizing spoilage and improving quality. Research from Deloitte indicates that integrating IoT with quality control processes can reduce defects by up to 30%, leading to more consistent product quality and increased customer satisfaction. As manufacturers harness these technologies, they will likely see notable improvements in production efficiency and waste reduction, ultimately contributing to a more sustainable food supply chain.

Furthermore, predictive analytics powered by IoT devices allows manufacturers to foresee equipment failures before they occur, reducing downtime and maintenance costs. According to a study by McKinsey, companies utilizing IoT for predictive maintenance have seen a reduction in maintenance costs by up to 25%. In a landscape where consumer demand for high-quality and safe food products continues to rise, IoT innovations will be pivotal in helping manufacturers maintain compliance with stringent quality standards while optimizing their operations.

Advancements in Food Processing Machinery for Enhanced Safety Standards

The food processing industry is undergoing a significant transformation, particularly with advancements aimed at enhancing safety standards in food making machinery. As we look toward 2025, emerging technologies are focusing on improving hygiene, reducing contamination risks, and ensuring compliance with stricter food safety regulations. This shift is largely driven by consumer demand for transparency and safety in food production.

One of the key trends in this landscape is the integration of IoT (Internet of Things) technology within food processing machinery. By utilizing connected devices, manufacturers can monitor equipment performance in real-time, allowing for proactive maintenance and ensuring that all machinery operates under safe conditions. Additionally, the use of advanced sensors can detect potential hazards, such as temperature fluctuations or cross-contamination, providing immediate alerts to prevent compromised food safety.

Another noteworthy development is the use of automation and robotics in food processing. Automated systems not only increase efficiency but also minimize human intervention, which is a common point for contamination. Enhanced cleaning technologies, such as self-cleaning mechanisms and antimicrobial materials, are also emerging, further bolstering safety measures. These innovations collectively contribute to a safer food production environment, ensuring that machinery meets high safety standards while enhancing operational effectiveness in the industry.

Top Food Making Machinery Trends to Watch in 2025 - Advancements in Food Processing Machinery for Enhanced Safety Standards

| Trend | Description | Impact on Safety | Projected Adoption Rate (%) |

|---|---|---|---|

| AI-Powered Machinery | Integration of artificial intelligence for real-time monitoring and process optimization. | Enhances precision in food safety protocols. | 65% |

| Automated Cleaning Systems | Use of robotics for efficient and thorough cleaning of equipment. | Reduces contamination risks significantly. | 70% |

| IoT Integration | Implementation of IoT devices for real-time data collection and analysis. | Improves tracking of safety compliance. | 55% |

| Sustainable Materials | Adoption of eco-friendly and safe materials in machine construction. | Reduces likelihood of chemical contamination. | 60% |

| Advanced Traceability Systems | Utilization of blockchain technology for enhanced traceability. | Ensures accountability in food safety. | 50% |

Key Market Drivers Influencing the Food Machinery Sector Growth by 2025

As the food machinery sector evolves, several key market drivers are shaping its growth trajectory towards 2025. Firstly, the increasing demand for automation in food production is transforming the landscape. Manufacturers are under pressure to enhance efficiency and reduce labor costs, leading to a significant shift towards automated machinery that can streamline production processes. This automation not only boosts productivity but also improves consistency and quality in food processing, meeting the rising consumer expectations for food safety and reliability.

Secondly, the growing focus on sustainability is driving innovation in food machinery. Companies are prioritizing eco-friendly practices and seeking out equipment that reduces energy consumption and minimizes waste. This trend is encouraging the development of machinery designed with advanced technologies, such as energy-efficient motors and systems that incorporate recyclable materials. As sustainability becomes a core value for consumers, food machinery manufacturers who align with these principles are likely to gain a competitive edge in the market.

Moreover, the shift towards healthier food options is influencing the types of machinery required in the sector. As more consumers seek nutritious and wholesome eating choices, food producers are adapting their processes to create healthier products. This translates to a demand for specialized machinery that can handle alternative ingredients and innovative food preparation techniques, thus fostering growth within niche markets and driving the need for ongoing technological advancements in food production equipment.