Top 10 Essential Food Machinery for Efficient Production and Processing

In the modern landscape of food production and processing, the role of food machinery has become increasingly pivotal in enhancing efficiency, safety, and sustainability. According to a report by the Food and Agriculture Organization (FAO), global food production must increase by approximately 70% by 2050 to meet the demands of an ever-growing population. This demand underscores the necessity for advanced food machinery that not only maximizes output but also minimizes waste throughout the production cycle.

Recent advancements in food technology have led to significant improvements in machinery, allowing for automation and precision that were previously unattainable. The International Society of Automation (ISA) notes that automated food processing can achieve productivity increases of up to 30%, while also improving quality control and reducing labor costs. As manufacturers strive to implement more efficient processes, understanding the essential food machinery available to optimize production becomes crucial. This overview highlights the top ten machinery types that are fundamental for food processing operations, each contributing uniquely to the overarching goal of efficient food production.

Essential Types of Food Machinery for Production Efficiency

In the ever-evolving food production landscape, the right machinery plays a crucial role in achieving efficiency and consistency. The global food processing machinery market is projected to reach approximately $65 billion by 2025, with an annual growth rate of 6% from 2020 to 2025, according to a recent industry report. Essential types of food machinery not only enhance production speed but also ensure product quality and safety, aligning with stringent food industry regulations.

Key types of food machinery contributing to production efficiency include mixers, conveyors, chillers, and packaging machines. For instance, high-capacity mixers facilitate the quick preparation of mixtures, which is particularly vital in bakeries and confectioneries. Conveyor systems streamline the flow of materials, reducing labor costs and minimizing waste. Furthermore, advanced chillers are essential for maintaining the freshness of perishable goods, allowing producers to extend shelf life while adhering to safety standards. Packaging machines play a significant role too, with automated solutions decreasing bottlenecks and increasing throughput. Together, these machines create a seamless production flow that optimizes operational efficiency, ultimately leading to improved profitability in the food industry.

Key Features of Food Processing Equipment to Look For

When choosing food processing equipment, several key features can significantly enhance production efficiency and product quality. One essential characteristic is versatility, allowing machinery to perform multiple tasks within the production line. This adaptability not only optimizes workflow but also reduces the need for numerous machines, saving space and operational costs. Operators should also look for user-friendly interfaces and control systems that simplify the management of production processes, ensuring that employees can easily adjust settings and monitor performance.

Another critical aspect is durability and ease of maintenance. Equipment that is built with high-quality materials and designed for easy access to components will minimize downtime and repair costs. Regular maintenance is vital in food processing, where hygiene standards are stringent; thus, machines should facilitate regular cleaning and sanitization without extensive disassembly. Furthermore, energy efficiency is becoming increasingly important, as it lowers operating costs and aligns with sustainability practices. Equipment that uses less energy while maintaining performance is a wise investment for any food production facility looking to improve its overall efficiency.

Top 10 Essential Food Machinery for Efficient Production and Processing

| Machine Type | Key Features | Applications | Efficiency Rating |

|---|---|---|---|

| Industrial Mixer | Variable speed, durable construction, easy cleanup | Baking, dough preparation, sauces | 95% |

| Centrifuge | High separation speed, low energy consumption | Dairy processing, juice extraction | 90% |

| Packing Machine | Automated sealing, adjustable settings | Snacks, beverages, frozen foods | 92% |

| Food Processor | Multi-function capabilities, quick slicing and dicing | Vegetable preparation, salad mixing | 85% |

| Fryer | Temperature control, efficient oil usage | Fried snacks, poultry, fish | 88% |

| Blender | High power motor, easy to clean | Smoothies, sauces, soups | 87% |

| Conveyor Belt | Adjustable speed, durable materials | Material handling, packaging | 94% |

| Refrigeration Unit | Energy efficient, temperature control | Cold storage, preservation | 90% |

| Oven | Even heat distribution, programmable settings | Baking, roasting, drying | 93% |

| Pasteurizer | High-temperature processing, capacity options | Dairy, beverages, sauces | 96% |

Best Practices for Maintaining Food Machinery Efficiency

Maintaining the efficiency of food machinery is crucial for optimizing production and ensuring high-quality processing. Regular maintenance checks are essential to identify wear and tear before it leads to machine failure. Establishing a routine schedule for inspections can help detect potential issues, allowing for timely repairs and minimizing downtime. It's important to keep a detailed log of maintenance activities, which can serve as a useful reference for future upkeep.

Tips: Always clean machinery components after use to prevent buildup of residues that can affect performance. Implement lubrication schedules based on the manufacturer's guidelines to reduce friction and wear in moving parts. Training staff on proper usage and maintenance techniques will also empower them to contribute to the longevity of equipment.

Another key aspect of maintaining food machinery efficiency is monitoring operating parameters. Ensuring that machines are calibrated correctly will help achieve optimal performance. Use monitoring systems to track metrics such as temperature, pressure, and speed, adjusting as necessary to maintain ideal conditions. Regularly reviewing these parameters can minimize energy consumption and improve overall productivity.

Tips: Encourage team members to report any unusual sounds or irregularities during operation. Keeping spare parts on hand can also reduce downtime significantly when repairs are necessary. Finally, developing a culture of continuous improvement among staff can lead to the discovery of new maintenance strategies and efficiency-enhancing practices.

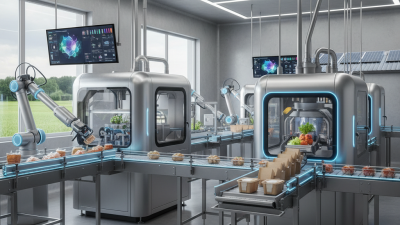

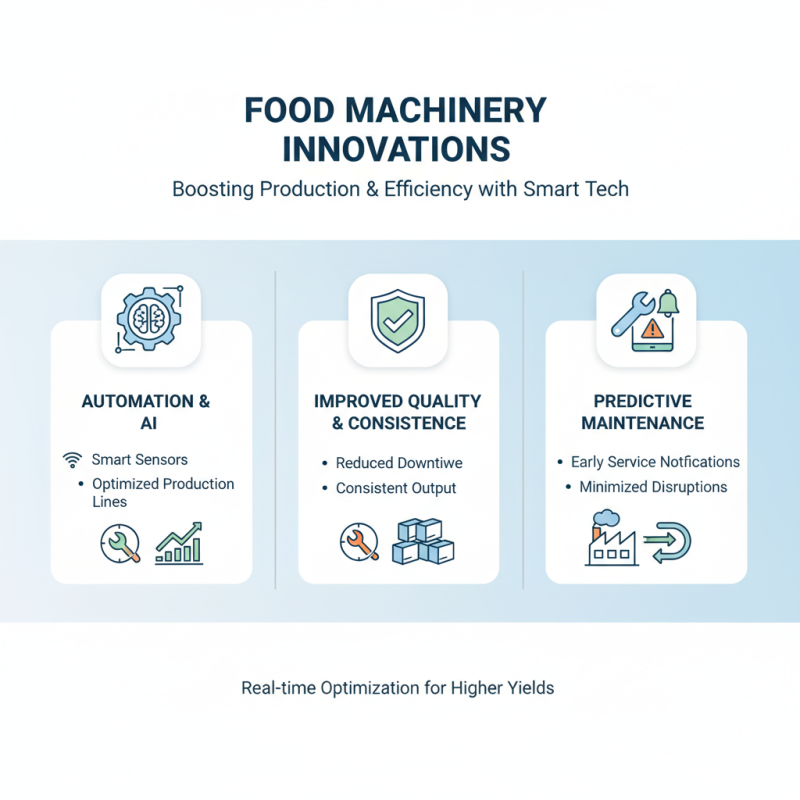

Innovations in Food Machinery Technology for Enhanced Output

Innovations in food machinery technology are revolutionizing the production and processing industry, significantly enhancing output and efficiency. With advancements in automation, machinery now integrates smart sensors and AI algorithms that optimize production lines in real-time. This allows manufacturers to reduce downtime, improve product quality, and ensure consistent output. For instance, predictive maintenance systems can notify operators when machines require servicing before a breakdown occurs, minimizing production disruptions.

Tips for implementing new food machinery technologies include starting with pilot programs to test innovations on a smaller scale before full-scale deployment. Additionally, investing in training for staff is crucial to maximize the potential of new systems. Educated employees can leverage the technology effectively, ensuring that production runs smoothly and efficiently. Furthermore, considering energy-efficient equipment helps reduce operational costs while promoting environmental sustainability.

As further innovations emerge, companies should continually assess their machinery and processes. Staying informed about the latest technological advancements can provide a competitive edge in the market. Streamlining operations not only boosts productivity but also enhances the overall quality of food products, catering to an increasingly discerning consumer base.

Impact of Food Machinery on Quality and Safety Standards

The integration of advanced food machinery in production and processing plays a crucial role in maintaining quality and safety standards within the food industry. High-quality machinery ensures that food products are prepared, processed, and packaged in a controlled environment, reducing the risk of contamination. Automated systems, for instance, minimize human interaction during production, which is a significant factor in preventing foodborne diseases. Furthermore, precise temperature and humidity controls significantly enhance the shelf life and integrity of food products, ensuring that they meet stringent safety regulations.

Moreover, the technological advancements in food machinery have led to more efficient tracking of quality metrics throughout the production process. Equipment equipped with sensors and data collection systems offers real-time insights into various parameters such as texture, flavor, and nutritional content. This not only helps to uphold food safety standards but also aids in complying with regulatory requirements. As food manufacturers increasingly embrace these technologies, they enhance their capability to deliver safe, high-quality food products while fostering consumer confidence in the food market.

Top 10 Essential Food Machinery for Efficient Production and Processing

This chart illustrates the impact of essential food machinery on production efficiency and quality standards in the food industry. Each type of machinery significantly contributes to operational effectiveness and safety compliance.