How to Choose the Best Food Product Packaging Machine for Your Business

In the rapidly evolving food industry, the significance of efficient and effective packaging cannot be understated. The global food packaging market is projected to reach a staggering USD 500 billion by 2025, driven by the growing demand for convenience and sustainability among consumers. As businesses strive to meet these emerging needs, investing in the right food product packaging machine has become paramount. Not only does it enhance the shelf life of food products, but it also plays a crucial role in brand presentation and compliance with health regulations.

Choosing the best food product packaging machine involves understanding various factors, including production speed, machine versatility, and the specific packaging requirements of different food categories. According to data from the Food Packaging Association, over 60% of consumers claim that packaging influences their purchase decisions, highlighting the importance of investing in high-quality packaging solutions. Moreover, with advancements in technology, modern packaging machines can offer capabilities such as automated labeling, resizing, and eco-friendly packaging options, making it easier for businesses to adapt to market demands while ensuring operational efficiency. By evaluating these aspects, companies can make informed decisions that will not only streamline their production processes but also enhance customer satisfaction and drive sales growth.

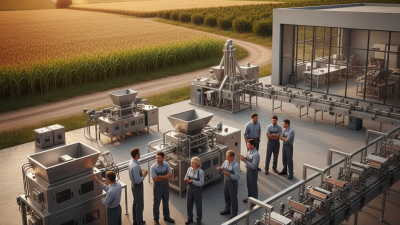

Understanding the Different Types of Food Packaging Machines

When it comes to selecting the right food packaging machine for your business, understanding the different types available is crucial. There are several key types of food packaging machines, including vacuum sealers, flow wrappers, and bottle filling machines.

Vacuum sealers are ideal for preserving the freshness of perishable items by removing air from the package.

Flow wrappers are versatile and can wrap a variety of food products efficiently, making them perfect for snacks, confections, and baked goods.

Bottle filling machines, on the other hand, are essential for liquid products, ensuring precise filling and sealing of jars and bottles.

Tips for choosing the right packaging machine include assessing your production volume and product type.

Consider how much you plan to produce daily or weekly, as this will influence the type of machine you need. Additionally, think about the characteristics of your product, such as size and packaging requirements, to find a machine that fits your needs.

It’s also wise to evaluate the machine’s ease of use and maintenance, as well as the availability of technical support.

Another important consideration is the machine’s ability to adapt to future changes in product lines or packaging styles.

As your business grows, you may want to diversify your product offerings or enhance your packaging aesthetics. Investing in flexible machinery that can accommodate new products will save you time and money in the long run.

Always conduct thorough research and consult with packaging experts when making your decision to ensure you choose the best food packaging machine for your operations.

Key Features to Consider When Selecting a Packaging Machine

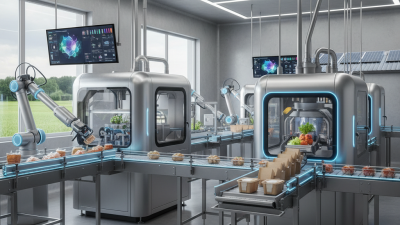

When selecting a food product packaging machine, there are several key features to consider that can significantly impact your business operations. First and foremost, evaluate the machine's versatility. A good packaging machine should accommodate various product sizes and types, allowing you to adapt to changing market demands without investing in additional machinery. This flexibility can help streamline your production process and reduce downtime.

Another crucial aspect is the machine's automation level. High automation can enhance efficiency, minimize labor costs, and reduce the chance of human error. Look for machines equipped with advanced technology, such as touch screens and sensors, which provide user-friendly controls and real-time monitoring. Choosing automated systems can also improve consistency in your packaging, ensuring that each product meets quality standards.

**Tip:** Always perform a trial run with the machine, if possible, to see how it handles your specific products before finalizing your decision.

Additionally, consider the durability and maintenance requirements of the packaging machine. A machine made from high-quality materials will not only last longer but also require less frequent repairs. Regular maintenance support from the manufacturer is a must; it helps keep your operations running smoothly.

**Tip:** Research the availability of spare parts and servicing options to ensure long-term reliability and support for your investment.

Assessing Production Volume and Speed Requirements

When choosing a food product packaging machine, understanding your production volume and speed requirements is critical to selecting the right equipment. According to a report by Smithers Pira, the global packaging market is projected to reach $500 billion by 2024, driven largely by the increasing demand for convenience and sustainability. Businesses must assess their production needs based on not only the volume of products they intend to package but also the speed of packaging required to meet market demand. In fast-paced environments, a machine with a higher throughput can significantly reduce bottleneck situations, ensuring efficient operation.

For instance, if a company plans to package 10,000 units per day, it is essential to select a machine capable of at least 500 units per hour to meet daily targets without overwhelming the operational workflow. Moreover, the speed of the machine should match the pace of the production line, which can often involve complementary processes such as filling and sealing. A balance between speed and production volume is crucial; too much emphasis on rapid output might compromise packaging integrity, leading to increased waste and product returns. Therefore, businesses should conduct a thorough analysis of their production capabilities, aligning packaging solutions with both immediate and future volume expectations.

Production Volume and Speed Requirements for Food Packaging Machines

Evaluating Budget and Cost-Effectiveness of Packaging Solutions

When evaluating budget and cost-effectiveness for packaging solutions, businesses must first consider the total cost of ownership (TCO) associated with different food packaging machines. According to a report by the Packaging Machinery Manufacturers Institute (PMMI), companies often overlook hidden costs like maintenance, labor, and energy consumption. For instance, a machine that appears cheaper upfront may result in higher long-term costs due to frequent breakdowns or inefficient energy usage. In fact, PMMI estimates that up to 25% of a machine's lifecycle costs arise from these ongoing expenses, underscoring the importance of evaluating a machine's reliability and operational efficiency before making a purchase.

Moreover, a comprehensive analysis of operational needs can lead to more informed investment decisions. The Food and Agriculture Organization (FAO) highlights that the right packaging equipment can increase production efficiency by up to 30%. Thus, while the initial investment in advanced packaging technologies may exceed budget constraints, the potential for enhanced productivity and lower per-unit costs can significantly elevate a company’s profit margins. By integrating the principles of lean manufacturing and automation, businesses can optimize their packaging processes, ensuring that the selected machine not only aligns with their budgetary requirements but also enhances overall operational performance.

Choosing Between Customization and Standard Packaging Options

When it comes to selecting a food product packaging machine, businesses face a crucial decision: whether to go with customization or standard packaging options. A study by MarketsandMarkets suggests that the global food packaging machinery market is projected to reach $32 billion by 2025, highlighting the growing importance of efficient and tailored solutions. Custom packaging can enhance brand recognition, improve shelf appeal, and cater to specific product requirements, which can be a decisive factor in a competitive marketplace. However, customization often comes at a premium, and companies must weigh the costs against potential benefits.

On the other hand, standard packaging solutions offer cost-effectiveness and quick deployment. According to a report by Mordor Intelligence, standard packaging machinery can reduce lead times significantly, allowing businesses to respond swiftly to market demand. For smaller businesses or those with limited budgets, opting for standard machinery might be a prudent choice, enabling them to focus resources on product quality and customer experience.

**Tips:**

1. Assess your production volume: If you're operating at a smaller scale, standard machines can be more suitable and less risky financially.

2. Evaluate your product specifics: If your product requires unique packaging or handling, investing in a customized solution may pay off in the long run.

3. Consider future growth: Choose a packaging solution that can adapt to your evolving business needs, whether that means upgrading standard machinery or integrating new custom features.

Related Posts

-

How to Choose Hygienic Food Packaging for Safe and Healthy Meals

-

2025 Guide: How to Choose the Best Agro Processing Machinery for Your Farm

-

Top 10 Essential Food Machinery for Efficient Production and Processing

-

Top 10 Food Machinery Innovations You Must Know About in 2023

-

Top Food Making Machinery Trends to Watch in 2025

-

Top 10 Innovations in Food Production Packaging for Sustainability and Safety