2025 Guide: How to Choose the Best Agro Processing Machinery for Your Farm

As the agricultural sector evolves, the significance of efficient agro processing machinery continues to grow. Farmers today are faced with the challenge of choosing the right equipment that not only enhances productivity but also aligns with their specific operational needs. The process of selecting the best agro processing machinery can be daunting, given the myriad of options available in the market. This guide aims to simplify that journey, providing valuable insights into the key factors to consider while making your decision.

Investing in the right agro processing machinery is critical for optimizing production and ensuring sustainability on your farm. From grain processing to value-added production, the efficiency and reliability of the machinery can significantly influence the quality of your output. Understanding your unique requirements, the scale of your operations, and the types of products you aim to produce are pivotal in making an informed choice. This guide will equip you with the necessary knowledge to assess various machines, evaluate their features, and ultimately select the equipment that best fits your farming objectives.

Understanding Agro Processing Machinery: An Overview

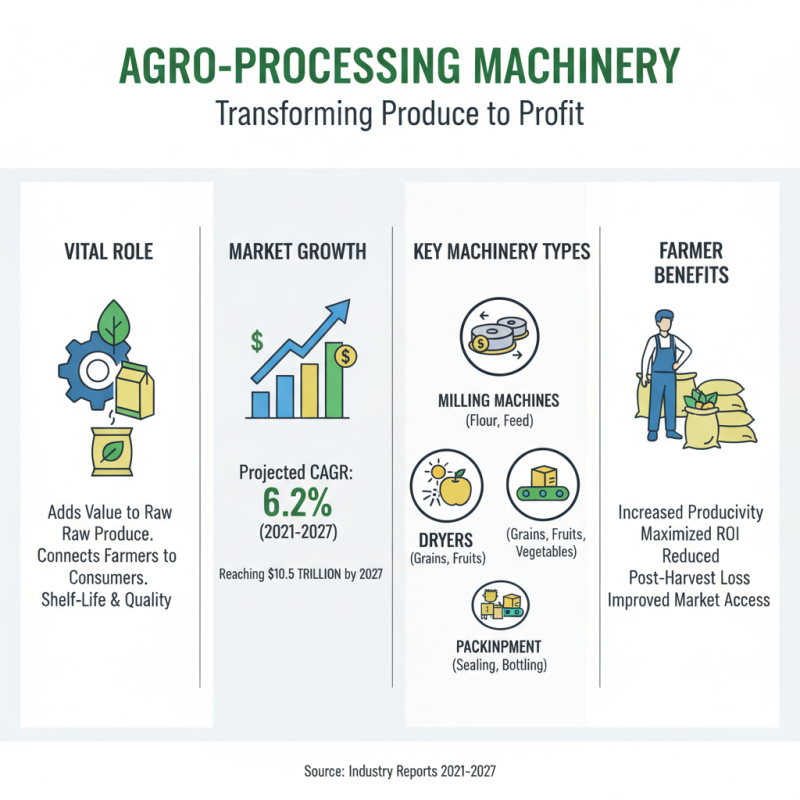

Agro processing machinery plays a vital role in the agricultural sector, transforming raw produce into value-added products that can reach consumers effectively. The global agro-processing market is expected to grow significantly, with a projected CAGR of 6.2% from 2021 to 2027, reaching approximately $10.5 trillion by the end of this forecast period. Understanding the types of machinery available, including milling machines, dryers, and packing equipment, is essential for farmers looking to enhance productivity and maximize their return on investment.

Investing in the right agro processing machinery not only boosts efficiency but also reduces post-harvest losses, which can be as high as 30% in some regions due to inadequate processing techniques. For instance, automated processing lines can significantly minimize labor costs and speed up production timelines, ensuring that farmers can respond swiftly to market demands. The choice of machinery should also take into account the specific needs of the farm, including the type and volume of produce, as well as the desired level of automation. In a landscape where sustainability and food safety are paramount, selecting energy-efficient and environmentally-friendly solutions can further benefit farmers by aligning with consumer expectations and regulatory standards.

Key Factors to Consider When Choosing Machinery for Your Farm

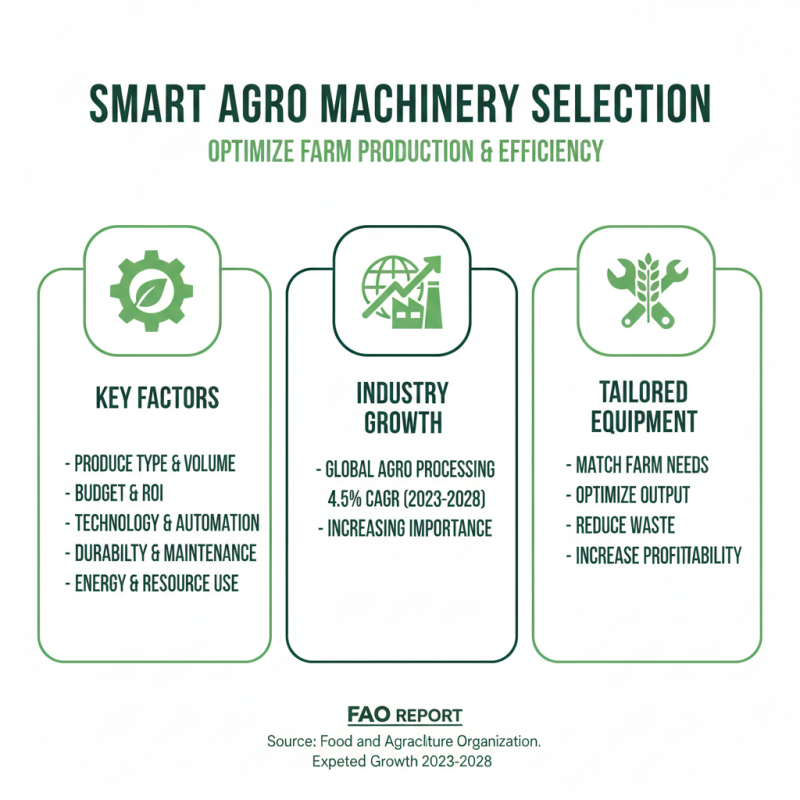

When selecting agro processing machinery for your farm, understanding the key factors that influence machinery choice is crucial for optimizing production and efficiency. According to a report by the Food and Agriculture Organization (FAO), the global agro processing industry is expected to grow at a CAGR of 4.5% from 2023 to 2028, highlighting the increasing importance of selecting the right equipment tailored to your agricultural needs.

One of the primary considerations is the type of processing you intend to perform. Different machinery serves various functions, such as milling, drying, or packaging. A study published in the Journal of Agricultural Machinery underscores the need for farmers to assess their specific processing requirements, as utilizing inappropriate machinery can lead to increased operational costs and reduced outputs. Additionally, factors like the machinery's capacity, energy consumption, and maintenance requirements significantly impact long-term productivity and profitability. By evaluating these aspects, farmers can make informed decisions that align with industry standards and technological advancements.

Furthermore, understanding the local agricultural landscape and market demands is essential. Reports indicate that tailor-made machinery solutions can enhance product quality and reduce waste, with some farms witnessing efficiency boosts of up to 30% after switching to specialized equipment. Engaging with local agricultural experts and leveraging data from agricultural research organizations can provide valuable insights into the best machinery suited for the specific crops and environmental conditions on your farm.

Types of Agro Processing Machinery and Their Applications

When selecting agro processing machinery for your farm, it is essential to understand the various types available and their specific applications. Common categories of agro processing machinery include fruit and vegetable processing equipment, grain milling machinery, dairy processing machines, and meat processing equipment. Each type serves unique functions that cater to different agricultural outputs. For instance, fruit and vegetable processing machines can significantly enhance shelf life and quality, yielding a 20-30% increase in profit margins, according to a report by the Food and Agriculture Organization (FAO).

In the realm of grain processing, milling machinery can convert raw grains into flour or other products, illustrating efficiency through automated processes that reduce labor costs by about 25%. Dairy processing equipment serves to pasteurize and homogenize milk, aligning with health standards and improving product stability, which is crucial in meeting consumer demand for safe dairy products. Meanwhile, meat processing machinery ensures compliance with strict hygiene regulations while maximizing yield and minimizing waste. A study by the International Journal of Food Science shows that utilizing advanced meat processing technologies can increase yield by up to 40%.

Tips: Assess your farm's specific needs based on the types of crops or livestock you have. Investing in multifunctional machines can also save costs and space. Additionally, consider the maintenance and technical support available for the machinery, as this can greatly affect your long-term investment.

Evaluating Machinery Efficiency and Productivity for Your Operations

When selecting agro processing machinery for your farm, evaluating efficiency and productivity is crucial. The right machinery can significantly enhance your operational capabilities, reduce labor costs, and improve product quality. Begin by assessing your specific processing needs and the volume of production to determine what machinery will best fit your operations. Consider factors such as output rate, energy consumption, and maintenance requirements, as these will impact your long-term cost efficiency.

Tips: Always compare different models and their specifications to understand which offers the best performance for your unique situation. Additionally, consider machinery that provides versatility for multiple processing tasks, as this can save both time and investment.

Moreover, it's essential to analyze the scalability of the machinery. As your farm grows, the equipment should be capable of adapting to increased production demands without a significant financial burden. Evaluate whether the machinery can be easily upgraded or expanded, ensuring it remains a viable option for years to come.

Tips: Consulting with experts and other farmers who have experience with specific types of machinery can provide valuable insights into performance and reliability, helping you make a more informed decision.

2025 Guide: How to Choose the Best Agro Processing Machinery for Your Farm

| Machinery Type | Efficiency (%) | Productivity (tons/hour) | Fuel Consumption (liters/hour) | Maintenance Frequency (months) |

|---|---|---|---|---|

| Combine Harvester | 85 | 10 | 6 | 12 |

| Tractor | 80 | 15 | 5 | 10 |

| Seed Drill | 90 | 8 | 3 | 15 |

| Plough | 75 | 6 | 4 | 8 |

| Baler | 88 | 12 | 4.5 | 10 |

Maintenance and Support: Ensuring Longevity of Agro Processing Equipment

Proper maintenance and support are critical components in ensuring the longevity of agro processing machinery. According to a recent industry report by the International Journal of Agricultural Engineering, regular maintenance can reduce machinery downtime by up to 30%, directly impacting productivity and profitability on the farm. Implementing a structured maintenance schedule that includes cleaning, lubrication, and adjustments can extend the life of your equipment significantly. Familiarizing yourself with the manufacturer's guidelines for maintenance can also help prevent common issues that lead to costly repairs.

Tips: Always keep a detailed log of maintenance activities to track performance and identify recurring issues. Additionally, consider investing in training for your staff to ensure they are proficient in handling the machinery and performing routine maintenance tasks. This knowledge empowers your team and creates a proactive approach to machinery support.

Another key aspect of ensuring the longevity of agro processing equipment is having access to reliable support services. A study by the Agricultural Machinery Association indicates that machinery supported by skilled technicians experiences 40% fewer failures compared to those with limited support. Establishing a relationship with experienced service providers can be invaluable. They can offer insights on best practices and provide timely assistance during breakdowns, further minimizing downtime and maximizing output.

Tips: When selecting a support service, prioritize providers who offer tailored maintenance plans and are familiar with your specific type of machinery. This ensures that you receive expert guidance and efficient repairs when needed, ultimately increasing the lifespan of your agro processing equipment.